The (iron) keel of a McVay Bluenose

Quote from Rozbot1987 on July 17, 2023, 11:00 amSince acquiring B250 about a year ago, (a boat that had previously sported the embarrassing monikers, "SNAFU", and "Blue Dragon") I have been looking for information and expertise on the design and construction of these boats. Its keel evidences swelling/cracking at the aft bottom near the rudder, and from what I can see in looking at other McVays on the hard, this is common place of cracking and failure.

(above: Starboard side, with 1" hole saw cut to inspect interior)

(above: Port side ("smile") crack)

Despite a rather large fleet of customised boats in Chester, so far, I have yet to find the Bluenose wizard/doctor who is responsible for converting so many cabintops into flattops and who would likely know more about their construction. So, in the absence of such expertise, my uncle, partner and I have been doing a lot of exploratory surgery.

As opposed to many of the boats that I've become accustomed to (Thunderbird, Soling), the McVay Bluenose is designed with a full keel, and with internal ballast. This much is obvious to anyone who knows anything about sailboats. And while this avoids the problems of keel bolts and that pesky hull/keel joint that can be the source of headaches, the McVay's configuration has some of its own deficiencies that need remedying in my case (and probably many others too).

I have heard speak of "keel delamination" in these boats, and in my opinion, this is a misnomer. The McVay Bluenose's entire hull and keel was molded of fibreglass before ballast was dropped in. This is "internal ballast". The ring on the iron ballast that was used by a crane for lowering it into the keel cavity is located just beneath the companionway to the cramped and unusable cabin (approximately where the cockpit scuppers are plumbed to through-hulls.

A photo of internal ballast (not from a Bluenose) for illustration purposes:

At best, the McVay Bluenose's iron ballast may have had some polyester compound (bodyfill) smeared on its sides and bottom as it was lowered into the fibreglass cavity sometime back in the 1970s. But from what I am able to tell, it was never laminated to the glass itself. The glass would have fully cured first. What this means is that a quest to "relaminate" (by use of epoxy or otherwise) the ballast to the keel is probably doomed to fail and would not really resolve the more urgent issues with the keel's construction (in my opinion).

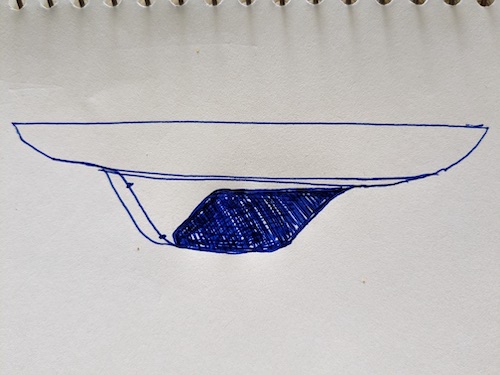

I have been told that some McVays used lead ballast, while others used iron. Mine is iron. It is possible that where lead ballast is used, the shape of the ballast is different given the density/weight of lead being different. For iron ballast, it is shaped (approximately as follows):

(In reality, the ballast probably does not come quite this far aft.)

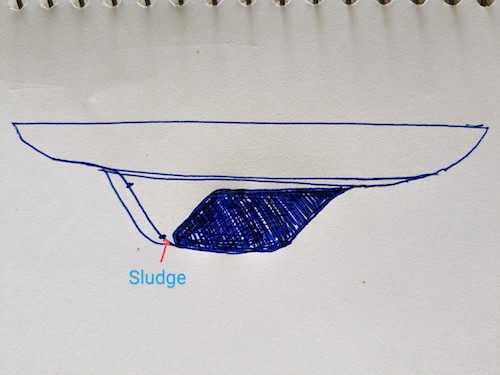

Note that there is a void ahead of the rudder bolts at the very bottom of the keel (where there is also no ballast). Note also the rather large cavity behind the ballast and in front of the rudder. Most McVays have plumbed a bilge pump hose that reaches down into this cavity. In theory, with enough diligence, this larger area can be kept dry. The small void at the bottom of the keel behind the ballast, however, is nearly impossible to keep fully dry. The plywood bulkheads of the boat which have become soft and flaky over the years, combined with whatever else may find its way into the bilge (duct tape, sandpaper, bits of line, you name it) will also eventually migrate into this lower pocket over time.

The result is that pumping it out will only become more difficult with time, as debris will clog the pump and produce a type of sludge that even a shop vac cannot remove. I suppose someone with a septic tank cleaning system might be able to remove this.

See below for a view from the top (inspection port cut into cockpit floor) looking down:

Once the sludge is removed, and this bottom cavity is cleaned, it will likely need to be filled with something to prevent this in the future. Foam? concrete? I will follow up this post with updates. For now, I figured this sort of analysis might be useful for others in the future. I have seen many other McVay bluenoses sitting on the hard with a split keel in this area. With some information sharing, we might be able to devise a fix for this to keep this area free of water and debris and more easily pumped out (including, perhaps the use of a drain plug).

Since acquiring B250 about a year ago, (a boat that had previously sported the embarrassing monikers, "SNAFU", and "Blue Dragon") I have been looking for information and expertise on the design and construction of these boats. Its keel evidences swelling/cracking at the aft bottom near the rudder, and from what I can see in looking at other McVays on the hard, this is common place of cracking and failure.

(above: Starboard side, with 1" hole saw cut to inspect interior)

(above: Port side ("smile") crack)

Despite a rather large fleet of customised boats in Chester, so far, I have yet to find the Bluenose wizard/doctor who is responsible for converting so many cabintops into flattops and who would likely know more about their construction. So, in the absence of such expertise, my uncle, partner and I have been doing a lot of exploratory surgery.

As opposed to many of the boats that I've become accustomed to (Thunderbird, Soling), the McVay Bluenose is designed with a full keel, and with internal ballast. This much is obvious to anyone who knows anything about sailboats. And while this avoids the problems of keel bolts and that pesky hull/keel joint that can be the source of headaches, the McVay's configuration has some of its own deficiencies that need remedying in my case (and probably many others too).

I have heard speak of "keel delamination" in these boats, and in my opinion, this is a misnomer. The McVay Bluenose's entire hull and keel was molded of fibreglass before ballast was dropped in. This is "internal ballast". The ring on the iron ballast that was used by a crane for lowering it into the keel cavity is located just beneath the companionway to the cramped and unusable cabin (approximately where the cockpit scuppers are plumbed to through-hulls.

A photo of internal ballast (not from a Bluenose) for illustration purposes:

At best, the McVay Bluenose's iron ballast may have had some polyester compound (bodyfill) smeared on its sides and bottom as it was lowered into the fibreglass cavity sometime back in the 1970s. But from what I am able to tell, it was never laminated to the glass itself. The glass would have fully cured first. What this means is that a quest to "relaminate" (by use of epoxy or otherwise) the ballast to the keel is probably doomed to fail and would not really resolve the more urgent issues with the keel's construction (in my opinion).

I have been told that some McVays used lead ballast, while others used iron. Mine is iron. It is possible that where lead ballast is used, the shape of the ballast is different given the density/weight of lead being different. For iron ballast, it is shaped (approximately as follows):

(In reality, the ballast probably does not come quite this far aft.)

Note that there is a void ahead of the rudder bolts at the very bottom of the keel (where there is also no ballast). Note also the rather large cavity behind the ballast and in front of the rudder. Most McVays have plumbed a bilge pump hose that reaches down into this cavity. In theory, with enough diligence, this larger area can be kept dry. The small void at the bottom of the keel behind the ballast, however, is nearly impossible to keep fully dry. The plywood bulkheads of the boat which have become soft and flaky over the years, combined with whatever else may find its way into the bilge (duct tape, sandpaper, bits of line, you name it) will also eventually migrate into this lower pocket over time.

The result is that pumping it out will only become more difficult with time, as debris will clog the pump and produce a type of sludge that even a shop vac cannot remove. I suppose someone with a septic tank cleaning system might be able to remove this.

See below for a view from the top (inspection port cut into cockpit floor) looking down:

Once the sludge is removed, and this bottom cavity is cleaned, it will likely need to be filled with something to prevent this in the future. Foam? concrete? I will follow up this post with updates. For now, I figured this sort of analysis might be useful for others in the future. I have seen many other McVay bluenoses sitting on the hard with a split keel in this area. With some information sharing, we might be able to devise a fix for this to keep this area free of water and debris and more easily pumped out (including, perhaps the use of a drain plug).